Flowsheet Development

Flowsheet Development Series – Tips and tricks

Whether an operation is new or old; easy-to-process or running the tail end stockpile of fines; one thing is certain: The process flowsheet will make or break the operation.

Tips and tricks to flowsheet development

Critical for both a new operation and when putting life back into an under-performing, existing operation, accurate development of the process flowsheet of a minerals separation plant (MSP) is a must. We will spend the next few weeks discussing the process of flowsheet development with a series of blogs to walk you through the entire process.

This week we are focusing on steps you should take before you begin. Next week we will discuss Best Practices.

The ‘Snowflake’ Effect

As with most of nature, no two deposits are alike, and so no one processing plant can be mass produced. To turn raw materials into saleable products requires proper technology selection, tailoring and placement. In addition to yielding precise products a plant must fall within a budget, be environmentally sound and be capable of maintaining specifications throughout the life of the operation, no matter the variations in mineral suite from one end of a deposit to the next.

Though this may seem a daunting task, the best operation for each deposit can be easily discovered if you better understand the process of developing an appropriate concentrator plant.

Let’s start with how you prepare to develop your flowsheet. Just like any business endeavor you first need to evaluate, establish goals and define your strategy.

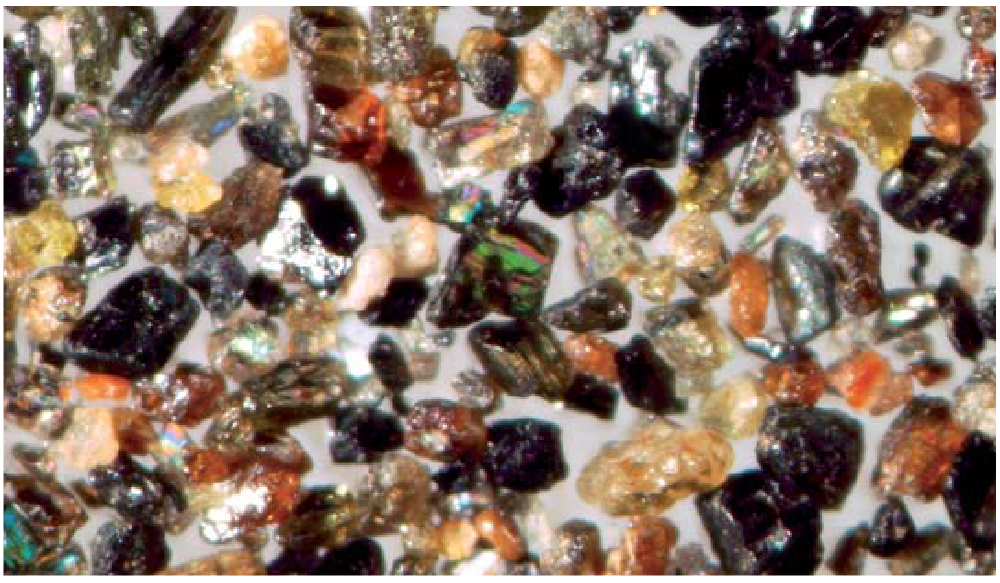

Microscopic grain counts can often yield valuable information to help determine best processing methods.

Before you begin:

Do your homework on the feed sample

Is the sample representative of the orebody, and not just an “easy to obtain” sample?

Ensure that you are working with representative material. If not, clearly understand the sample’s origin, and any processing steps already being implemented on the material prior to receipt.

Properly characterize feed

Ensure your characterization work on the feed is performed with the proper sampling techniques.

Understand the size-range of the deposit.

Determine the nature of the deposit’s valuable minerals.

Define the process development guidelines

What is the scope of testing?

Which component recoveries are important and how are they to be measured?

Example: In working with heavy minerals (HM), is overall HM recovery the right gauge, or does the trash, light heavy content warrant a VHM recovery approach?What are the final product goals?

Example: What are the needed product specifications? Do you need to perform simple chemical analysis or does your end-user require specific tests, such as: particle size distribution, mineralogic impurity reduction, etc. to meet an industry specific quality or requirement?

Taking the time to prepare and understand before you embark on any testing will help to ensure you develop a flowsheet that will yield profitability for the life of the process. As always, IMSC Group has a team of experts and an in-house testing facility to help you through every phase of designing an optimum process. Contact Us to discuss your needs.

Next week our series will focus on overall best practices in process development.